How to manufacturing drinks vending machine in Africa

- Introduction to Manufacturing Drinks Vending Machines

- Understanding the Drinks Vending Machine Industry

- Initial Design and Concept Development

- Selecting Advanced Materials and Components

- Hardware Manufacturing and Assembly

- Embedded Software and IoT Integration

- Quality Control and Compliance Testing

- Packaging, Logistics, and After-Sales Support

- Conclusion

- Frequently Asked Questions

Introduction to Manufacturing Drinks Vending Machines

The drinks vending machine market is a continuously expanding sector within the unmanned retail industry, driven by advances in technology and changing consumer behaviors. As a high-tech company with over 10 years of R&D experience, MAKMIK specializes in smart vending machine solutions including beverage vending machines. This comprehensive guide outlines the manufacturing process of drinks vending machines, integrating hardware engineering, software development, and IoT technology to meet the growing demand for automated retail.

Understanding the Drinks Vending Machine Industry

Drinks vending machines represent a critical component in the new retail ecosystem, providing convenient access to beverages in public spaces, offices, and high-traffic areas. According to recent market reports, the global beverage vending machine market is projected to grow at a CAGR of approximately 4.5% from 2023 to 2030, with increasing adoption in China, North America, and Europe.

Key trends influencing manufacturing requirements include energy efficiency, user interface innovations, and integration with mobile payment platforms. MAKMIK’s strategic focus on intelligent software and hardware solutions allows us to design machines that are responsive to these evolving market dynamics.

Initial Design and Concept Development

The manufacturing process begins with detailed design and prototyping. MAKMIK employs cross-functional teams involving industrial designers, mechanical engineers, and software developers to conceptualize machines that balance functionality, durability, and user experience.

Critical design factors include the machine’s capacity, type of beverages dispensed (e.g., bottled drinks, canned beverages, cold brew coffee), refrigeration systems, and customization options for touchscreens and payment methods. Utilizing CAD software, MAKMIK creates precise 3D models to simulate performance and ergonomics before production.

Selecting Advanced Materials and Components

The backbone of reliable drinks vending machines is the use of high-quality materials and components that ensure longevity and hygiene. Makers typically select stainless steel or powder-coated steel for the machine chassis to resist corrosion and wear.

In refrigeration, MAKMIK integrates energy-efficient compressors and advanced cooling units compliant with environmental regulations such as RoHS and REACH. The selection of dispensing mechanisms – whether spiral coils for bottles or drop systems for cans – is crucial to minimize product damage and maintain smooth operation.

Hardware Manufacturing and Assembly

MAKMIK’s production facility, spanning over 20,000 square meters, incorporates fully automatic assembly lines alongside CNC machining centers and laser cutting devices. This automation ensures precision in manufacturing components such as payment modules, display panels, and vending actuators.

The assembly process involves modular construction: first assembling refrigeration and dispensing units, integrating payment systems including NFC and QR code readers, then installing IoT sensors for real-time monitoring. Optical welding technology is used to secure components without compromising the casing’s airtightness.

Embedded Software and IoT Integration

Drinks vending machines today demand intelligent software to manage inventory, transactions, and user interfaces effectively. MAKMIK specializes in developing embedded firmware that interfaces with cloud-based management platforms using IoT protocols.

The software stack includes secure payment gateways, remote diagnostics, and real-time inventory management. IoT sensors embedded in key points (temperature, door sensors, stock levels) enable proactive maintenance and data analytics to maximize uptime and customer satisfaction.

Quality Control and Compliance Testing

Strict quality control is paramount in vending machine manufacturing. MAKMIK enforces rigorous testing protocols, including stress tests for mechanical parts, thermal performance assessments for refrigeration units, and software validation for e-payment reliability.

Compliance with regional safety standards such as CE (Europe), UL (United States), and CCC (China) is mandatory, ensuring that machines meet all electrical safety and environmental criteria. Regular audits, both in-process and post-production, guarantee that every drinks vending machine leaving the production line meets MAKMIK’s superior quality benchmarks.

Packaging, Logistics, and After-Sales Support

Once manufacturing is complete, proper packaging is essential to protect vending machines during shipment. MAKMIK uses custom crates with internal shock absorption to prevent damage, especially for sensitive electronic components.

Post-delivery, MAKMIK offers comprehensive after-sales services including installation support, remote monitoring, and maintenance contracts. This service model ensures longevity and client satisfaction, which are crucial for maintaining MAKMIK’s reputation as a global leader in unmanned vending solutions.

Conclusion

Manufacturing drinks vending machines is a sophisticated process requiring a blend of cutting-edge hardware production, innovative software development, and stringent quality control. Leading companies like MAKMIK leverage over a decade of experience and state-of-the-art production technologies to meet the modern retail sector’s needs. With the global beverage vending market expanding rapidly, investing in smart, reliable, and scalable vending machine manufacturing processes is essential for long-term success in this dynamic industry.

For more information about MAKMIK’s vending machine solutions, visit our website at makmiktech.com.

Frequently Asked Questions

What are the main components of a drinks vending machine?

The main components include the chassis, refrigeration system, dispensing mechanism, payment system, touchscreen/display panel, and embedded software.

How does MAKMIK ensure quality in vending machine production?

MAKMIK employs automated assembly lines, CNC machining, laser cutting, and thorough testing protocols complying with international safety standards to maintain quality.

What role does IoT play in modern drinks vending machines?

IoT enables remote monitoring, real-time inventory control, and predictive maintenance, enhancing machine uptime and user experience.

Can vending machines be customized for different beverages?

Yes, MAKMIK designs machines with flexible dispensing options suitable for cans, bottles, fresh beverages, and more, tailored to client requirements.

How does MAKMIK handle after-sales service?

MAKMIK offers installation support, remote diagnostics, and maintenance services to ensure reliable operation and customer satisfaction.

Benefits of Fragrance Vending Machines for Small Businesses

Tips for Wholesale vending machine for beauty products

Wholesale perfume vending machine manufacturer and supplier

What are the application scenarios of perfume vending machine for sale?

FAQ

Do you provide installation and maintenance services?

Yes, we offer comprehensive installation and maintenance services to ensure your vending machines operate smoothly.

What payment options do your vending machines support?

Our vending machines support various payment methods, including cash, credit/debit cards, mobile payments, and contactless payments.

Are your vending machines energy-efficient?

Yes, our vending machines are designed with energy-efficient technologies to reduce power consumption and minimize environmental impact.

What is the lead time for manufacturing and delivery?

Lead times vary based on the type and quantity of vending machines ordered, but we strive to deliver within 6-8 weeks from the date of order confirmation.

What kind of technical support do you offer?

We provide 24/7 technical support, including troubleshooting, repair services, and remote assistance to resolve any issues promptly.

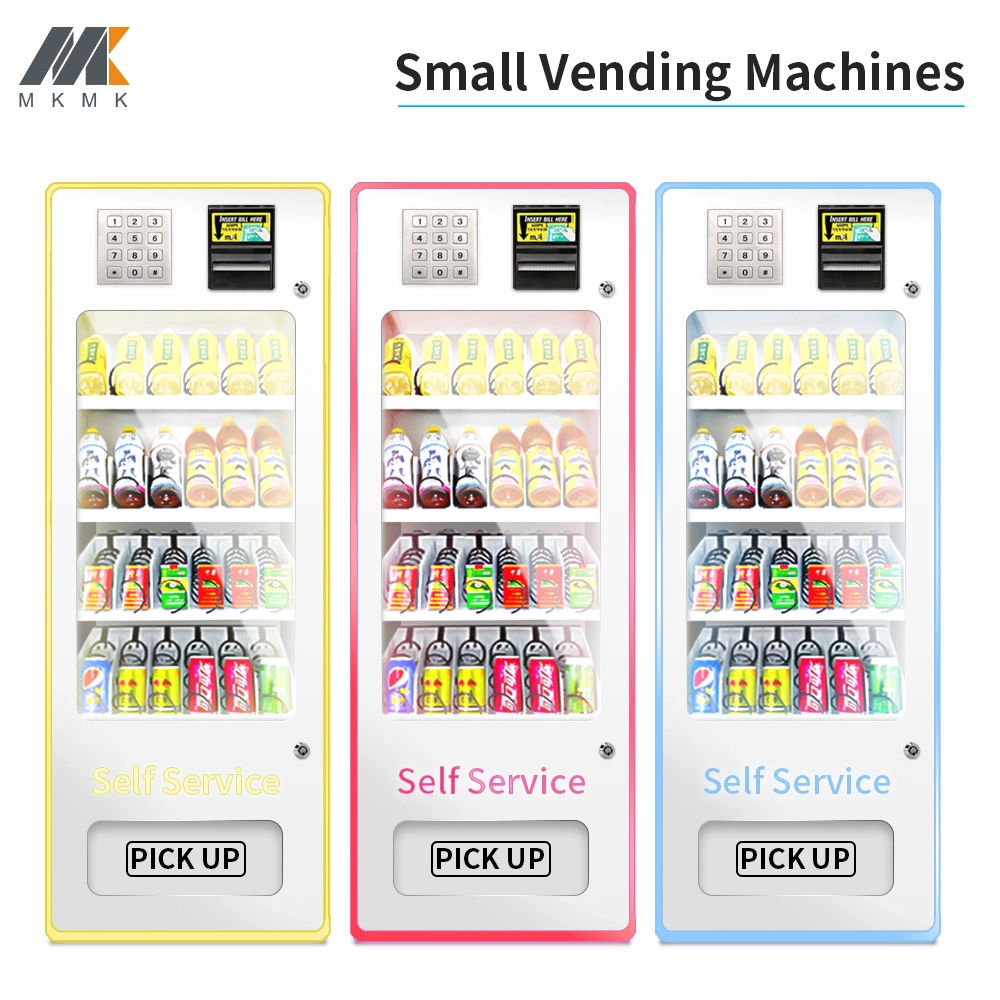

Medium-Sized Drinks Vending Machine With Small Screen or Keyboard

Introducing the MAKMIK Middle Size Drinks Vending Machine, the perfect solution for convenient beverage access. Engineered for versatility and efficiency, this drinks vending machine offers a wide selection of refreshing options. Enhance your space with MAKMIK's reliable and user-friendly vending experience. It is ideal for use in offices, schools, and public venues.

The machine is small, at room temperature, and can hold a variety of beverages and snacks. It comes with a small screen or keyboard.

Perfume Vending Machine Ten-Hole Integrated Model MK-PMS001

Introducing the MAKMIK Perfume Vending Machine, the Ten-Hole Integrated Model MK-PMS001. Designed to revolutionise fragrance accessibility, this cutting-edge perfume spray vending machine offers a seamless, user-friendly experience. Perfect for high-traffic areas, it will enhance your environment with convenient, on-demand scents. It will elevate your space with elegance and efficiency.

The machine can be customised in terms of appearance and functions according to actual needs, and there are multiple ways to combine. It will also acquire customers quickly.

Perfume Vending Machine Wall-Mounted Cabinet Model MK-PM-bs002

Discover the MAKMIK Perfume Vending Machine Wall-Mounted Cabinet Model MK-PM-bs002, an innovative perfume dispenser vending machine. Designed with convenience and style in mind, it integrates seamlessly into any space, offering an unparalleled fragrance experience. It is ideal for enhancing environments with a touch of luxury.

Perfume Vending Machine Split Base Model MK-PMT003

Introducing the MAKMIK Split Base Model MK-PM001, a cutting-edge perfume vending machine designed for modern convenience. This smart vending solution offers seamless operation and a sleek design, bringing the latest in fragrance technology to your fingertips. Elevate your space with the perfume vending machine by MAKMIK.

Customisable appearance and functions according to actual needs, multiple ways to combine, fast customer acquisition.

© 2025 MAKMIK | All Rights Reserved.

Facebook

Linkedlin

YouTube

Instagram

Twitter

Tik Tok